Igwe anaghị agba nchara, a corrosion-resistant alloy of iron with a minimum of 10.5% chromium, has become a ubiquitous material in various industries due to its unique properties. As a seasoned expert in the field of metal materials from Sino igwe anaghị agba nchara, having spent years working with stainless steel and other alloys, I will delve into the ụdị igwe anaghị agba nchara dị iche iche na akara ule ha, providing a comprehensive overview of their characteristics, applications, and advantages.

Different Types of Stainless Steel and Their Grades:

Firstly, let’s discuss the two primary categories of stainless steel: austenitic na martensitic. Austenitic stainless steel, the most common type, is non-magnetic and possesses excellent corrosion resistance. It contains high levels of chromium na nickel, which give it its characteristic corrosion resistance and ductility. Austenitic stainless steel grades such as 304 and 316 are widely used in construction, food processing, and medical equipment due to their ease of welding, formability, and overall corrosion resistance.

On the other hand, martensitic stainless steel is magnetic and exhibits higher strength and hardness than austenitic grades. It contains less nickel and more carbon, which allows it to be heat-treated to achieve desired mechanical properties. Martensitic stainless steel grades, such as 410 na 440, are often used in knives, cutting tools, and automotive components where high strength and wear resistance are required.

Now, let’s delve into the specific grades of stainless steel. 304 ogo, bụkwa nke a maara dị ka 18/8 igwe anaghị agba nchara, is the most commonly used grade. It contains 18% chromium and 8% nickel, providing good corrosion resistance and ductility. Grade 304 is suitable for a wide range of applications, including kitchenware, chemical processing equipment, and building materials.

Ọkwa 316 igwe anaghị agba nchara is a variation of 304 with the addition of molybdenum, which enhances its corrosion resistance, particularly against chloride ions. This grade is often used in marine environments, chemical processing, and other applications where exposure to corrosive substances is likely.

Grade 410 is a martensitic stainless steel that offers good corrosion resistance and high strength. It is commonly used in applications that require both corrosion resistance and mechanical strength, such as fasteners, valves, and surgical instruments.

Grade 430 is a ferritic igwe anaghị agba nchara that contains high levels of chromium but lacks nickel. It is magnetic and exhibits good corrosion resistance, making it suitable for decorative applications such as automotive trim and appliances.

Grade 440, particularly grade 440C, is a high-carbon martensitic stainless steel known for its excellent hardness and wear resistance. It is often used in knife blades, surgical instruments, and other applications where sharpness and durability are crucial.

In addition to these common grades, there are numerous other specialized stainless steel grades available, each designed to meet specific requirements. For instance, duplex stainless steel grades, such as 2205, combine the corrosion resistance of austenitic stainless steel with the strength of martensitic grades, making them suitable for demanding applications in the oil and gas industry.

The selection of stainless steel grade depends on the specific requirements of the application. Factors such as corrosion resistance, mechanical properties, formability, weldability, and cost all play a role in determining the most suitable grade. As a metal materials expert, I often advise clients to carefully consider these factors when making material selection decisions.

Furthermore, it’s worth noting that the properties and performance of stainless steel can be further enhanced through various surface treatments, such as polishing, passivation, and coating. These treatments can improve corrosion resistance, enhance aesthetics, and extend the lifespan of stainless steel components.

mmechi

In conclusion, stainless steel is a versatile material with a wide range of grades and applications. From common grades like 304 and 316 to specialized grades designed for specific uses, the choice of stainless steel grade is crucial in ensuring the success of any project. As the field of metal materials continues to evolve, it’s essential for engineers and designers to stay informed about the latest advances in stainless steel technology to make the most informed material selection decisions.

Daalụ maka ịgụ isiokwu anyị na anyị nwere olileanya na ọ ga-enyere gị aka ịghọta nke ọma nke ụdị igwe anaghị agba nchara dị iche iche na akara ule ha. If you are looking for stainless steel supplier and manufacturer online now, we would advise you to visit Sino igwe anaghị agba nchara.

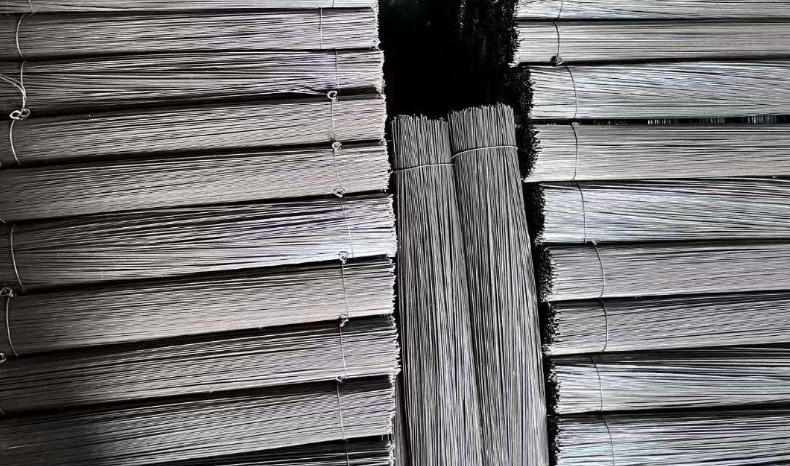

Dị ka onye na-eweta ngwaahịa igwe anaghị agba nchara sitere na Shanghai China, Sino igwe anaghị agba nchara na-enye ndị ahịa oke mma. igwe anaghị agba nchara ịchọ mma Ibé akwụkwọ, tubes igwe anaghị agba nchara, igwe anaghị agba nchara ọkpọkọ, igwe anaghị agba nchara, igwe anaghị agba nchara, efere igwe anaghị agba nchara, na igwe anaghị agba nchara na ọnụ ahịa dị oke asọmpi.

:+86-18621535697

:+86-18621535697  :export81@huaxia-intl.com

:export81@huaxia-intl.com