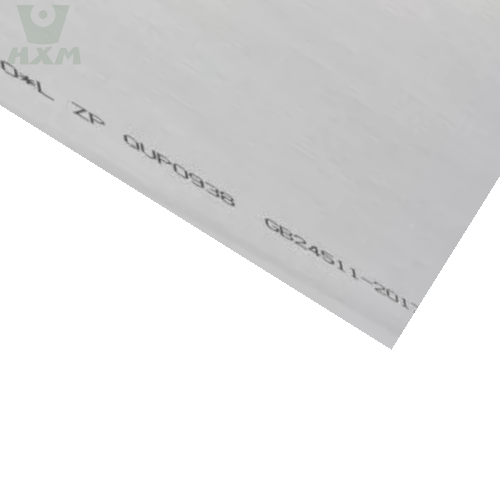

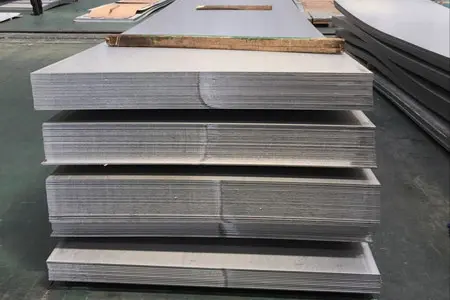

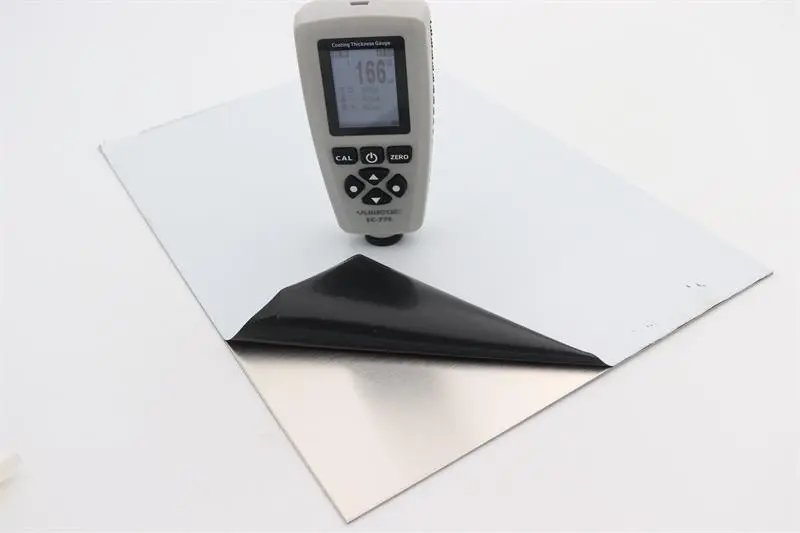

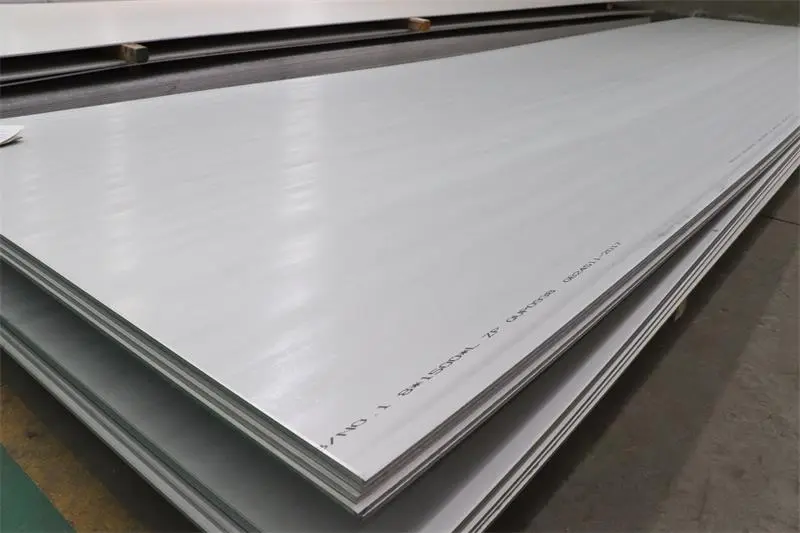

S31803 Hot Rolled igwe anaghị agba nchara efere

Na-achọ ihe kacha mma igwe anaghị agba nchara?

Họrọ sino-stainless-steel.com maka mkpa gị niile!

Igwe anaghị agba nchara 31803 Hot Rolled na-enye oke mma na ọnụ ahịa asọmpi, nke ọrụ ndị ahịa pụrụiche kwadoro.

:+86-18621535697

:+86-18621535697  :export81@huaxia-intl.com

:export81@huaxia-intl.com